Call us now

07971549477

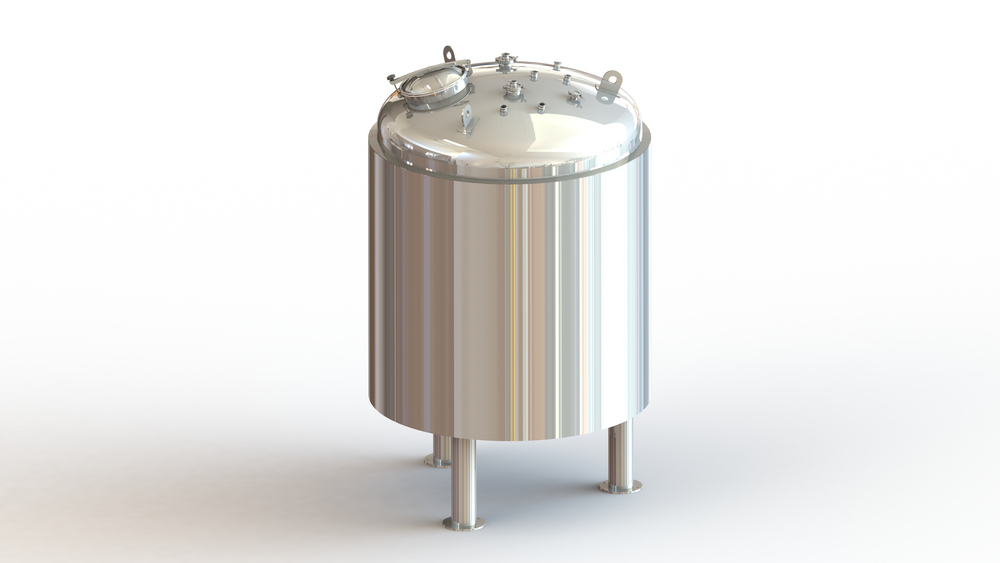

Stainless steel tanks are highly durable and versatile storage vessels designed to store, process, or transport liquids, gases, or bulk solids. These tanks are made of stainless steel, a material known for its resistance to corrosion, strength, and longevity. Stainless steel tanks are used in various industries, including food and beverage, pharmaceuticals, chemicals, and oil and gas, and are manufactured according to custom specifications.

-Key Features of Stainless-Steel Tanks

1.Material Composition:

Grade of Stainless Steel: The most commonly used stainless steel grades for tanks are 304, 316, and 316L. Each grade offers different levels of corrosion resistance, with 316 being preferred for highly corrosive environments such as food processing or pharmaceutical manufacturing.

Corrosion Resistance: Stainless steel provides excellent protection against rust, corrosion, and chemical degradation, making it ideal for long-term storage of liquids or chemicals.

2.Customization:

Tailored Designs: Stainless steel tanks can be fabricated in a wide range of shapes, sizes, and features based on the specific requirements outlined in customer-provided drawings. This customization can include specific dimensions, inlet/outlet placements, support structures, or internal features.

Shapes and Configurations: Tanks can be designed as vertical, horizontal, cylindrical, square, cone-bottom, or other specialized shapes depending on the purpose and available space.

3.Durability and Longevity:

Stainless steel is durable and long-lasting, even in harsh environments. It resists rust, oxidation, and staining, ensuring the tank maintains its integrity over time.

4.Welded Construction:

Stainless steel tanks are often welded, creating smooth, seamless connections between sections to minimize the risk of leaks or contamination. TIG (Tungsten Inert Gas) welding is commonly used for food and pharmaceutical tanks to maintain hygienic standards.

5.Seamless Finish and Smooth Surface:

The surface finish of the stainless-steel tank can be customized, from a rough finish for industrial applications to a polished, sanitary finish (mirror-like) for industries requiring sterile environments like food and pharmaceuticals.

6.Pressure and Vacuum Resistance:

Stainless steel tanks can be designed to withstand varying pressures and vacuum conditions, making them suitable for both pressurized and atmospheric storage applications.

7.Thermal Insulation:

Depending on the purpose, some stainless-steel tanks come with thermal insulation to maintain temperature-sensitive contents, such as chemicals, oils, or food products. Insulation can be applied in the form of jackets or built-in layers.

-Types of Stainless-Steel Tanks

1.Storage Tanks:

Purpose: Used for storing liquids, powders, or gases.

Designs: Can be vertical or horizontal, with flat or conical bottoms depending on the application.

Applications: Often used in industries such as chemicals, brewing, and water treatment.

Customization: The design can include special features such as ladders, manways, venting systems, sight glasses, and inspection ports.

2.Mixing Tanks:

Purpose: These are equipped with agitators or mixing devices to combine multiple ingredients or chemicals.

Designs: Mixing tanks may have internal baffles or other mechanisms to ensure proper mixing.

Applications: Common in the pharmaceutical, cosmetic, food, and beverage industries.

Customization: Tank designs are often tailored to ensure optimal flow dynamics, temperature control, and material properties, as per customer specifications.

3.Pressure Vessels:

Purpose: Tanks designed to hold gases or liquids at pressures higher than atmospheric pressure.

Designs: Typically have reinforced walls and are built to withstand high pressures or vacuum conditions.

Applications: Used in industries such as petrochemical, natural gas, and industrial gas storage.

Customization: The design can include pressure relief valves, temperature sensors, and reinforcement for high-pressure storage.

4.Heat Exchanger Tanks:

Purpose: Used to transfer heat between two fluids without mixing them.

Designs: These tanks often feature internal coils or plates through which one fluid passes while the other flows around it to transfer heat.

Applications: Common in industries such as dairy processing, chemical production, and oil refining.

Customization: Custom-designed heat exchanger tanks may include specific coil patterns, multiple fluid inlets/outlets, or thermal insulation.

5.Fermentation Tanks:

Purpose: Used in the fermentation process, primarily in the food and beverage industry.

Designs: Typically come with built-in temperature controls, venting systems, and mixing or agitation mechanisms.

Applications: Brewing, winemaking, and pharmaceutical fermentation processes.

Customization: Fermentation tanks can be designed with specialized fittings for monitoring fermentation progress, such as pressure gauges, temperature probes, and sampling ports.

6.Sanitary Tanks:

Purpose: Designed to meet stringent hygienic standards, these tanks are often used in the food, pharmaceutical, and biotechnology industries.

Designs: Features a smooth, polished finish, and sanitary welds to minimize contamination risks.

Applications: Used for storing food products, beverages, chemicals, and pharmaceuticals.

Customization: These tanks can be customized to include features such as CIP (Clean-In-Place) systems, easy-to-clean surfaces, and sterile venting.

7.Wastewater Treatment Tanks:

Purpose: Used in the treatment and storage of wastewater or other waste products.

Designs: Often large with conical or flat bottoms to facilitate sedimentation and treatment processes.

Applications: Municipal and industrial wastewater treatment plants.

Customization: Tanks can be customized with specific inlet/outlet arrangements, internal mixing components, or aeration systems.

8.Cryogenic Tanks:

Purpose: Designed to store liquids at extremely low temperatures, such as liquid nitrogen or liquid oxygen.

Designs: Typically double-walled with insulation to prevent heat transfer.

Applications: Used in the medical, food, and chemical industries.

Customization: Cryogenic tanks can be customized to include special insulation materials, venting systems, and temperature sensors for safe storage and handling.

Applications of Stainless-Steel Tanks

1.Food and Beverage Industry:

Brewing: Fermentation tanks, storage tanks for liquids, and mixing tanks for beer or wine production.

Dairy: Tanks for storing milk, cream, and other dairy products.

Juice Production: Tanks for storing fruit juices and syrups, which need to maintain purity and freshness.

2.Chemical Industry:

Chemical Storage: Tanks for holding chemicals, solvents, or acids. Stainless steel™s resistance to corrosion makes it an ideal material for this purpose.

Mixing Tanks: Tanks used to mix chemical compounds for processing.

3.Pharmaceutical Industry:

Sterile Storage: Stainless steel tanks are used for the sterile storage of pharmaceuticals, chemicals, or biological agents.

Drug Manufacturing: Mixing, blending, and reaction tanks used in drug production.

4.Oil and Gas Industry:

Storage Tanks: Stainless steel is used in tanks for storing crude oil, natural gas, and other petroleum products, due to its resistance to corrosion in harsh environments.

Cryogenic Tanks: For storing liquefied natural gas (LNG) and other gases at extremely low temperatures.

5.Water Treatment:

Wastewater Treatment: Stainless steel tanks are used for storing and treating wastewater before it is released or reused.

Potable Water Storage: Stainless steel tanks are also used for potable water storage due to their clean and durable properties.

Stainless steel are highly customizable storage and processing solutions used across multiple industries. They are designed for durability, resistance to corrosion, and performance in challenging environments. By selecting the right design and specifications, businesses can optimize their production, storage, and distribution systems. Whether used for mixing, fermentation, storage, or chemical processing, stainless steel tanks offer a reliable and long-lasting solution.

Price:

Price 60000 INR / Number

Minimum Order Quantity : 1 Unit

Power : 25

Features : Durable and corrosionresistant

Weight (kg) : 50

Capacity : 50

Price 60000.00 INR / Number

Minimum Order Quantity : 1 Piece

Power : 25

Features : Good Quality

Weight (kg) : 50

Capacity : 25